Article

Databricks and Crosser: Resolving Manufacturing Quality with Machine Vision and MLOps - Edge to Cloud

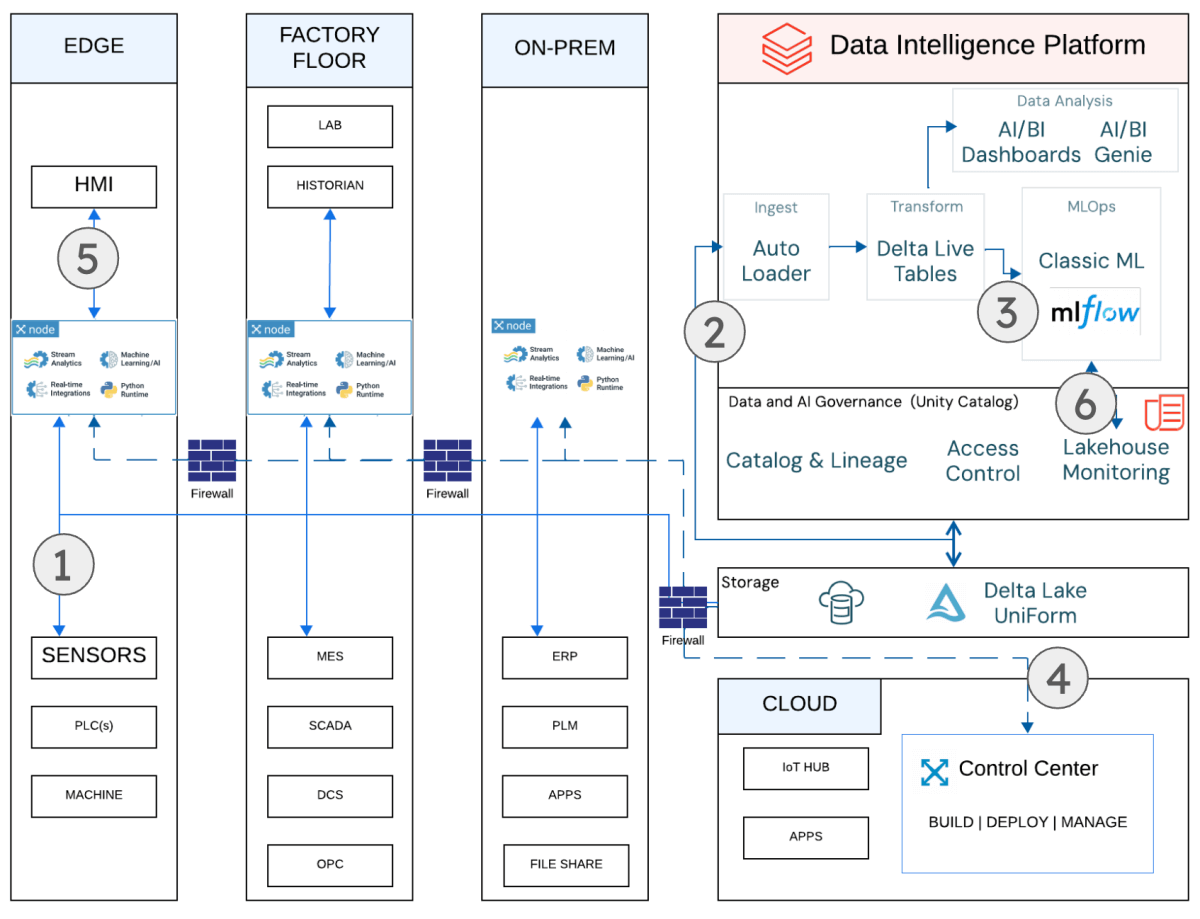

In today’s fast-paced manufacturing environments, ensuring consistent quality requires more than just data collection — it demands real-time, intelligent action. In collaboration with Databricks, we explore how combining Crosser’s edge analytics platform with Databricks’ Mosaic AI tools enables manufacturers to orchestrate a seamless, event-driven machine vision solution across the production line.

This end-to-end approach connects to any manufacturing data source, from legacy equipment to IoT sensors, enabling immediate detection of process variations and prescriptive actions that prevent defects before they escalate. By leveraging YOLO-based machine vision models trained in the cloud and deployed via ONNX at the edge, manufacturers can accelerate defect detection, reduce downtime, and continuously improve through automated model retraining — all while keeping operational costs and latency low.

Highlights from the joint solution:

- Real-time defect detection with low-latency edge processing.

- Automated model retraining using intelligent data pipelines.

- Seamless deployment of YOLO-based models to resource-constrained edge devices.

- Full MLOps lifecycle with unified governance and monitoring.

- Continuous quality improvement through IT/OT convergence.

Discover how Crosser and Databricks are enabling industrial AI at scale and unlocking a new level of manufacturing quality.

Read the full article on Databricks.com